Quality Assurance

What We Do

Quality Assurance

Heat Treating & Zinc Electroplating

Morgan Ohare’s success is directly related to its commitment to customer service and quality. We have quality and environmental management systems in place and are ISO 9001:2015 registered and feature ISO 17025 accredited labs (American Association for Laboratory Accreditation).

Besides ensuring the highest quality zinc electroplating and heat treating, Morgan Ohare uses the following procedures and equipment:

Heat Treating – Quality Steps

- All purchase orders are reviewed to insure proper processing.

- All orders are weighted to verify complete production of customer’s product.

- All orders are automatically pre-washed to insure proper heat treat quality.

- All orders are Quality Approved with inspector sign-off before movement out of the department

- We maintain lot integrity

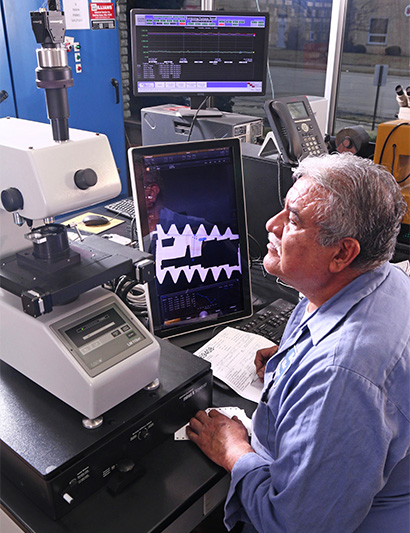

Heat Treat Test Equipment

- Two Micro Hardness testers

- Two Rockwell Hardness testers

- Mount makers and polishers

Heat Treat Test Procedures

- Case hardness and depth testing for all Case Hardened orders

- Core Hardness for all orders

- Decarburization Tests performed on each Neutral Hardened order

- A2LA Certificate of Accreditation

Plating Department - Quality Steps

- All purchase orders are reviewed to insure proper processing

- All parts are automatically pre-washed to insure proper plating quality

- All orders are weighed to verify complete production of customer’s product

- All orders are Quality Control Approved before movement out of the department

Plating Test Equipment

- Three X-Ray Fluorescent Plating Thickness Testers

- Salt Spray Cabinet – Operated per ASTM B117

Plating Test Procedures

- Computer Control System used to monitor and control all parameters of plating components

- A2LA Certificate of Accreditation

- Process Control operators on all shifts

- We maintain lot integrity